Chemists Design Faster Production Process to Study Glycans

Aug, 2020 - By SMI

Share

Chemists from Utrecht University designed a faster production process for essential sugars.

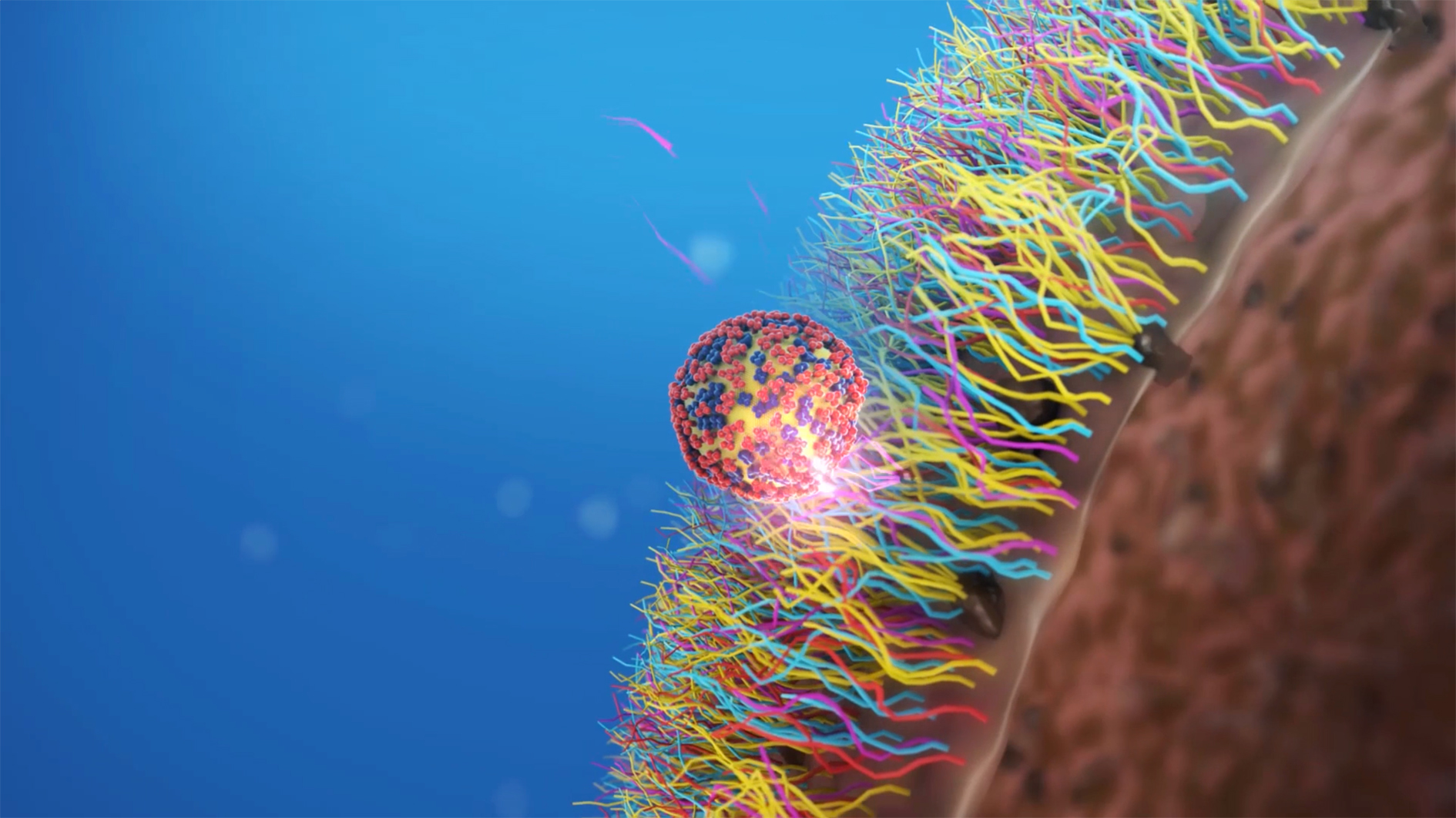

In various biological and disease processes, glycans play a major role. It can be used as a biomarker to identify cancer cells, but they are also essential components of most bio-based pharmaceuticals. However, glycans are more complex than DNA or proteins and almost 100 chemical steps are required to produce glycans in the lab.

Researchers developed a new method by starting from a glycopeptide, which can be easily obtained from egg yolk powder, as a building block for producing glycans. Trimming of glycopeptide is the first step in the new production process. Trimming is done until only the trunk and the branching points are left. Each branching point can be individually activated or deactivated by the researchers, which will allow them to re-grow the branches one-by-one by unblocking each of them individually and then administering enzymes that can build specific branches. This will allow the researchers to attach the glycan's asymmetrical branches to the trunk in a controlled manner.

The production process was cut down to ten steps by the researchers by using this new method. Geert-Jan Boons, one of the researchers, said, “We used the glycopeptide to produce the substance glycosyl-asparagine, an amino acid containing a sugar. We then put the glycosyl-asparagine through five chemical and enzymatic steps resulting in a compound having two branches. After this first process, we then used recombinant enzymes to produce a glycosyl-asparagine with four branches in just five additional steps.” This is the main compound for the production of a wide range of N-glycans.

Share

Stratagem Market Insights

533 Airport Boulevard, Suite 400, Burlingame, CA 94010, United States

Delivery Center

403, 4th Floor, Bremen Business Center

Aundh, Pune, Maharashtra 411007

India